A reliable power supply and robust network design are the foundations of a dependable marine electronics system. Without stable power and careful attention to network reliability, even the best instruments can fail when you need them most. This article covers essential principles and practical tips for managing power and ensuring your marine instrument network is reliable in the challenging marine environment.

It comes down to just three points:

- A clean, stable power supply:

- Good environmental conditions: (temperature, humidity and vibration)

- Cleanliness: You would be surprised to know how many faults on board are caused by filth and neglect – just because you don’t see your electrical connections every day doesn’t mean that you shouldn’t give them some love now and again!

Why Power Management Matters

Marine electronics networks like NMEA 2000 rely on a stable, clean power supply to function correctly. Voltage drops, surges, or interruptions can cause devices to reset, lose data, or even suffer permanent damage.

Proper power management ensures:

- Continuous operation of critical navigation and safety equipment

- Protection against electrical faults and corrosion

- Extended lifespan of your electronics and batteries

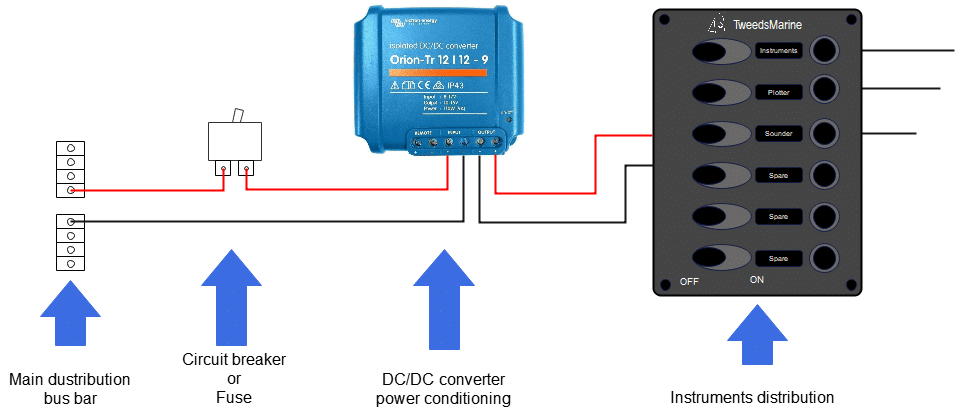

Install a power conditioning device: For the last several years, I have been recommending and installing an isolated DC/DC converter specifically for the electronics circuits on all installations.

A DC/DC converter is a device that is normally used to convert one DC voltage, say 24V, to another, say 12V, but they can also be used to condition a power supply. These devices can tolerate wide input voltage variations, noise and voltage spikes and maintain a clean stable output.

These units from Victron are good value for money and reliable. This model comes in 9, 18 and 30A models. I have no affiliation with Victron, just a lot of good experiences with their gear; they are middle of the road in price, and their stuff generally does what it says on the tin.

Designing a Robust Power Supply for Your Network

I assume that your vessel has a good battery and charging system. These comments are aimed specifically at the circuits supplying your onboard electronics.

Use Marine-Grade materials

- Always use marine-grade, tinned copper wiring sized appropriately for the current load and cable length.

- Connect your network power to a dedicated circuit protected by the correct fuse or circuit breaker (3A for the NMEA 2000 backbone 12V supply).

- Avoid sharing power circuits with high-draw devices like bilge pumps or lighting to prevent voltage dips.

Fuse and Circuit Protection

- Install fuses or circuit breakers as close as possible to the battery’s positive terminal. As a general rule, each time you step down in a size in wire gauge you must fuse appropriately.

- Use marine-rated fuse holders and circuit breakers that are specifically designed for resistance to vibration and moisture.

Label all circuits clearly for easy troubleshooting.

Battery Management

- Use quality marine batteries suited to your vessel’s power demands (Flooded deep cycle, AGM, or lithium as appropriate).

- Regularly check battery voltage and state of charge.

- Install a battery monitor integrated with your network for real-time data.

- Separate starting and house batteries, properly isolated to prevent accidental drain.

Backup Power and Redundancy

- For critical systems, consider a backup power source such as a secondary battery bank.

- Use automatic charging relays or DC-DC chargers to maintain backup batteries.

- Ensure your network devices can gracefully handle power interruptions without data loss.

Corrosion Prevention

- Use dielectric grease on important connectors to prevent moisture ingress.

- Choose marine-grade connectors and enclosures with appropriate IP ratings.

- Inspect connections regularly and clean if necessary.

You can get various conformal coating sprays and greases that can be sprayed over busbars, etc.. However, I discourage this as it makes working on those systems a misery. It’s Better to design the placement of the connections so that they are kept clean and dry.

Ensuring Network Reliability

Regular Maintenance and Testing

- Periodically inspect cables and connectors for wear or damage.

- Use diagnostic tools or MFD network status screens to verify device connectivity.

- Update device firmware and software to benefit from bug fixes and improvements.

Environmental Considerations

- Protect network components from excessive heat, vibration, and moisture.

- Use enclosures rated for marine environments and mount devices securely.

- Plan cable routes to avoid chafing and mechanical stress.

Practical Tips and Best Practices

- Label all cables and connections for easier troubleshooting.

- Leave service loops in cables near connectors to allow movement without strain.

- Colour-code power wires (red for positive, black or yellow for negative) to avoid confusion.

- Document your network layout and power circuits for future reference.

- Train yourself and/or your crew on basic troubleshooting to quickly identify and fix issues.

Network Reliability Troubleshooting Flowchart

Provided that you have implemented everything discussed here and looked after your boat’s systems well, you should have very few problems. But when you do, basic troubleshooting on an NMEA 2000 network is easy. Follow this flowchart and isolate the faulty device quickly.

Summary

Power management and network reliability are critical to the success of your marine electronics system. By designing a robust power supply, protecting against electrical hazards, and following best practices for network wiring and maintenance, you ensure your instruments perform reliably when it counts. Investing time and care in these areas pays dividends in safety, convenience, and peace of mind on the water.

You may have noticed that I have consistently specified “marine-grade”. This is not just a marketing slogan used by the manufacturers, although you are correct to be sceptical of labelling from some sources. The marine environment is harsh, and if you want a reliable system, then spend the extra money on “marine grade” from reputable brands. I know it hurts, but you won’t regret it.

Networking Marine Instruments FAQ

What is marine electronics networking?

Marine electronics networking refers to the interconnection of various marine electronic devices on a boat, such as GPS, sonar, engine instruments, and autopilots, to share data and improve functionality and reliability.

What are the main marine networking standards?

The two primary standards are NMEA 0183 and NMEA 2000. NMEA 0183 is an older, simpler serial communication protocol, while NMEA 2000 is a newer, more robust CAN-bus based network allowing multiple devices to communicate simultaneously.

What is NMEA 0183 and how does it work?

NMEA 0183 is a point-to-point serial communication protocol that transmits data in sentences at a fixed baud rate. It typically connects one talker (transmitter) to one or multiple listeners (receivers) using simple wiring.

What is NMEA 2000 and how does it differ from NMEA 0183?

NMEA 2000 is a multi-drop CAN bus network that allows multiple devices to communicate on the same network cable. It supports higher data rates, more complex data types, and improved reliability compared to NMEA 0183.

How do I convert between NMEA 0183 and NMEA 2000?

Conversion requires a dedicated gateway or converter device that translates the data protocols between NMEA 0183 and NMEA 2000, enabling older devices to interface with newer networks.

Can I connect my PC to NMEA 0183 or NMEA 2000 networks?

Yes, with appropriate interfaces and converters, you can connect a PC to either network for monitoring, logging, or control purposes. DIY guides exist for building such interfaces.

What are the best practices for installing marine electronics networks?

– Use proper marine-grade cables and connectors.

– Keep network cables away from power cables to reduce interference.

– Use correct termination resistors on NMEA 2000 networks.

– Plan the network topology carefully to avoid signal degradation.

– Ensure devices have proper power supply and grounding.

How reliable are marine instrument networks?

Marine networks are designed for high reliability with galvanic isolation, robust wiring and error-checking protocols. Proper installation and maintenance, along with a robust power supply are key to network reliability.

Can analogue sensors be integrated into NMEA 2000 or NMEA 0183 networks?

Yes, analogue sensors can be connected to NMEA 2000 and NMEA 0183 networks using interface modules that convert analogue signals into digital data.

What are common challenges in marine electronics networking?

– Compatibility issues between devices from different manufacturers.

– Signal interference and cable damage.

– Incorrect network termination or wiring errors.

– Difficulty in troubleshooting complex networks.

Where can I learn more about marine electronics networking?

I recommend some books below. Several manufacturers have great guides that you can read online or download. Actisense, Maretron, Garmin and Digital Yacht have a lot of good material.

3 Comments

[…] fuses, and circuit breakers is essential for reliable and safe operation. See this article, Boosting Marine Network Reliability: 3 Essential Areas to Improve for […]

[…] This article, part of my series on networking marine electronics, describes some of the typical problems with power supplies and gives guidance on establishing a reliable power supply aboard. Power Management and network reliability […]

[…] This article, part of my series on networking marine electronics, describes some of the typical problems with power supplies and gives guidance on establishing a reliable power supply aboard. Power Management and network reliability […]